Meet the 2024-25 trophy designers

At FIRST Tech Challenge UK, innovation isn’t just about robots. It’s about creativity, problem-solving and teamwork. This year, we provided our teams with a brand-new challenge: design the trophies for our regional qualifying tournaments.

Our trophy design competition invited teams to showcase their creative thinking and product design talents. Provided with a brief on size, materials and quantity, our teams were tasked with designing trophies fit for manufacture that also made a nod to this year’s game theme, INTO THE DEEP.

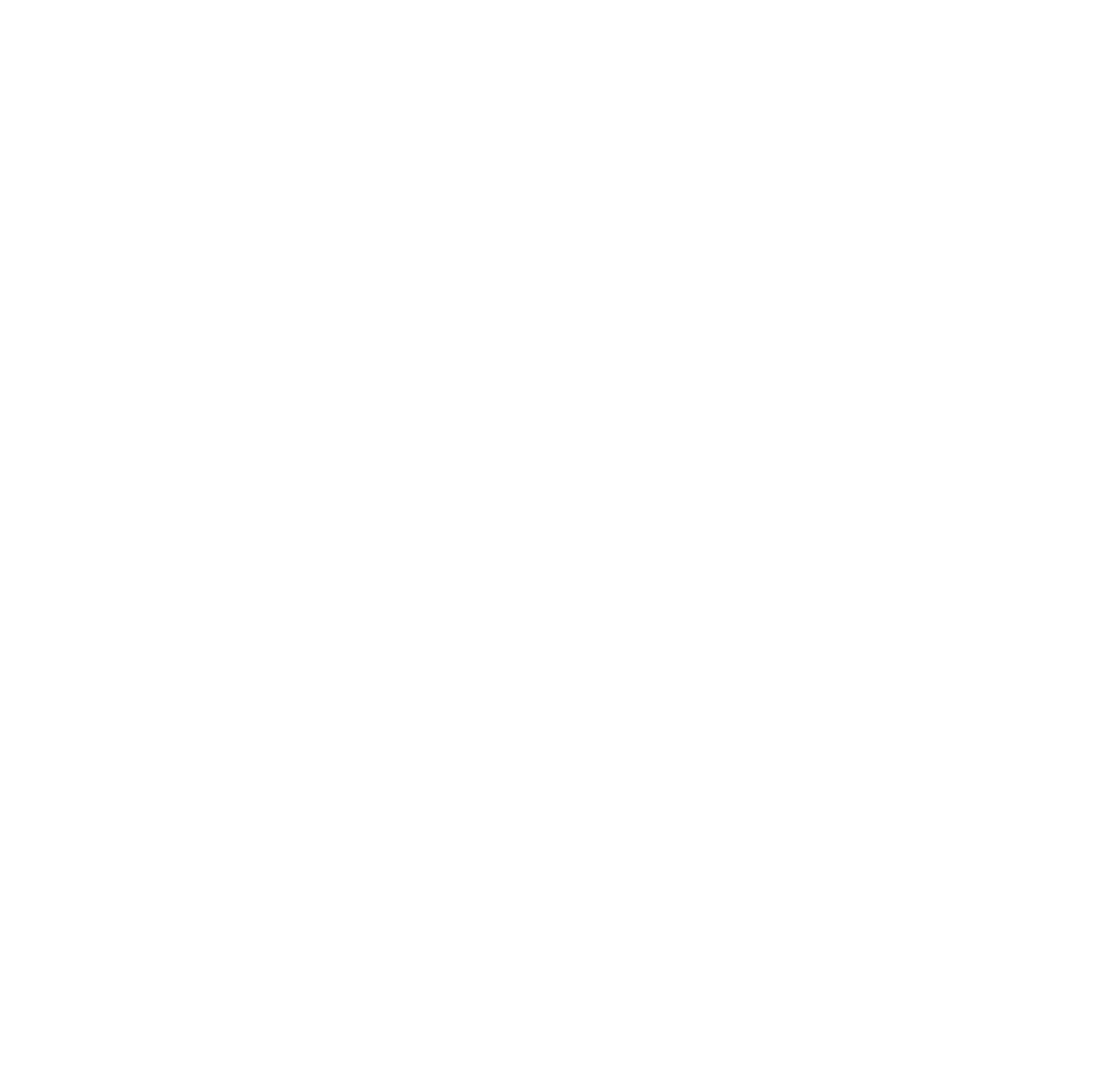

From initial pencil sketches to final CAD designs, these trophies reflect the diverse skills of our community. We’re thrilled to introduce their designers to you, Emily and Emmanuel. Over 200 trophies later, their creations are being used across the UK at all 15 of our regional qualifying tournaments.

Regional Inspire Award, designed by Emily from Team UltraViolet

My name is Emily and I lead the all-girls robotics team, UltraViolet, from Bournemouth School for Girls. Over the three years my team has been competing, we’ve had some pretty impressive achievements. Winning the National Inspire Award in 2023-24, to our outreach in our local community and even having the honour of representing Great Britain in the FIRST Global Challenge 2024.

My name is Emily and I lead the all-girls robotics team, UltraViolet, from Bournemouth School for Girls. Over the three years my team has been competing, we’ve had some pretty impressive achievements. Winning the National Inspire Award in 2023-24, to our outreach in our local community and even having the honour of representing Great Britain in the FIRST Global Challenge 2024.

This season, I entered the trophy design competition along with many other students from across the country to design the INTO THE DEEP awards for the UK Qualifying Tournaments. My love of product design, which I take for A-Level, led to spending quite a while coming up with a design that fits seamlessly with this year’s aquatic theme.

My inspiration for the shape of the trophy comes from the sea trench featured in the INTO THE DEEP season logo. Although not the most glamorous feature to model the design from, the V-shape mimics that of the cup in the classical trophy. From this, the submitted design had extrusion cut at angles to act as the sides, shaft spaces between layers of transparent acrylic to look like bubbles and a diver illuminating the “More Than Robots” logo. Following the brief, I also researched the materials to estimate the cost of a trophy and came to the startling realisation of how expensive such small parts can be! As a result, I removed the spacer bubbles to make more space for logos.

After winning the competition, I was asked to make the Inspire Award trophies. I worked with the fantastic team at American School London to make the design more fit for manufacturing by replacing the extrusion with 3D printed sides and designing a slimmer wooden base. ASL then cut and printed the plastic parts in London and shipped them to Bournemouth for the next production stage.

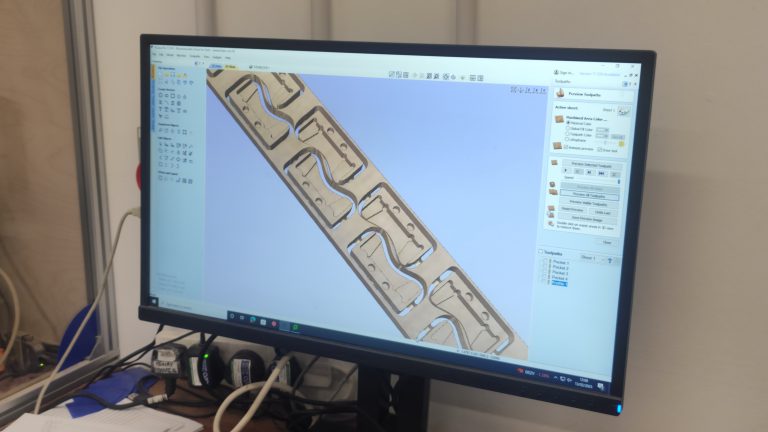

Emily’s CAD design for the base

In my school workshop, I used a large CNC router to cut the trophy bases out of upcycled beech. These parts had to be finished and sanded by hand before the two halves were assembled with dowels and a mallet. Once I waxed the bases, I assembled the plastic parts and secured them in the bases, ready to be shipped back to London for the plaques to be fitted.

Throughout the design and manufacturing process, I learnt so many new skills that I will be able to take back to the workshop. And although it has been a lot of hard work – and hours of sanding – it has been so worth it to see so many people with massive grins across their faces, holding up a trophy I designed. I hope all the Regional Inspire Award winners will feel like they have an awesome trophy to take home.

Regional Award trophies, designed by Emmanuel from P4F Robotics

My name is Emmanuel and I am a proud member of the Passion4Fusion youth group, competing with P4F Robotics in Edinburgh. This is our second year in FIRST Tech Challenge UK, and despite the obstacles we faced last season, we thrived – winning the Inspire Award at the Scottish regionals and the Motivate Award at the UK Championship. These victories were a testament to our perseverance, overcoming challenges such as limited time, funding and expertise in our first season.

My name is Emmanuel and I am a proud member of the Passion4Fusion youth group, competing with P4F Robotics in Edinburgh. This is our second year in FIRST Tech Challenge UK, and despite the obstacles we faced last season, we thrived – winning the Inspire Award at the Scottish regionals and the Motivate Award at the UK Championship. These victories were a testament to our perseverance, overcoming challenges such as limited time, funding and expertise in our first season.

This season, I had the incredible opportunity to design the majority of the competition’s regional trophies, and I want to share my journey.

Taking on the challenge

When I first saw the opportunity, I thought it was a fantastic initiative – giving young people a chance to showcase their creativity.

As the deadline approached, I remained uncertain how I’d fit it around my busy schedule. Then, five days before the submission date, I saw the opportunity again and I decided to go for it. I carefully read the specifications, ensuring I fully understood the requirements. The key takeaway? The design had to be simple and related to INTO THE DEEP, this season’s theme.

The design process

Since I had only started learning AutoCAD a few months before, I aimed to create something straightforward yet meaningful. I began designing in Autodesk Fusion, but soon found it challenging and lost motivation. I hesitated to continue until my elder sister gave me the push I needed. She didn’t just encourage me to participate – she believed I could win. That confidence fuelled my determination.

I took inspiration from the ocean, incorporating wave patterns into the trophy to align with the season’s theme. With just three days left, I completed my CAD design. The next day, I worked on the trophy’s front panel, adding the various logos required. As an experienced graphic designer, this part was much easier. Finally, I exported the design in pictorial, orthographic and auxiliary views, combined them into a PDF, and submitted it two days before the deadline.

The winning moment

When I received the email that my design had won, I was overjoyed! I shared the news with my family, some teammates including Ethan, Excelsis and Eman, and mentors Uncle Justin, Uncle Greg and Aunty Helena, who had supported me throughout my journey.

Having my trophy design used across the UK with the Passion4Fusion logo is a rare and special honour. I am truly grateful to the organisers at FIRST UK for this opportunity.

Trophies from the community

A massive thank-you goes to the American School in London for helping bring these stunning designs to life.

Stay tuned with our qualifying tournaments on socials at @ftc_uk on Instagram, X and TikTok. Follow us on LinkedIn for updates.